TEF-MAG®

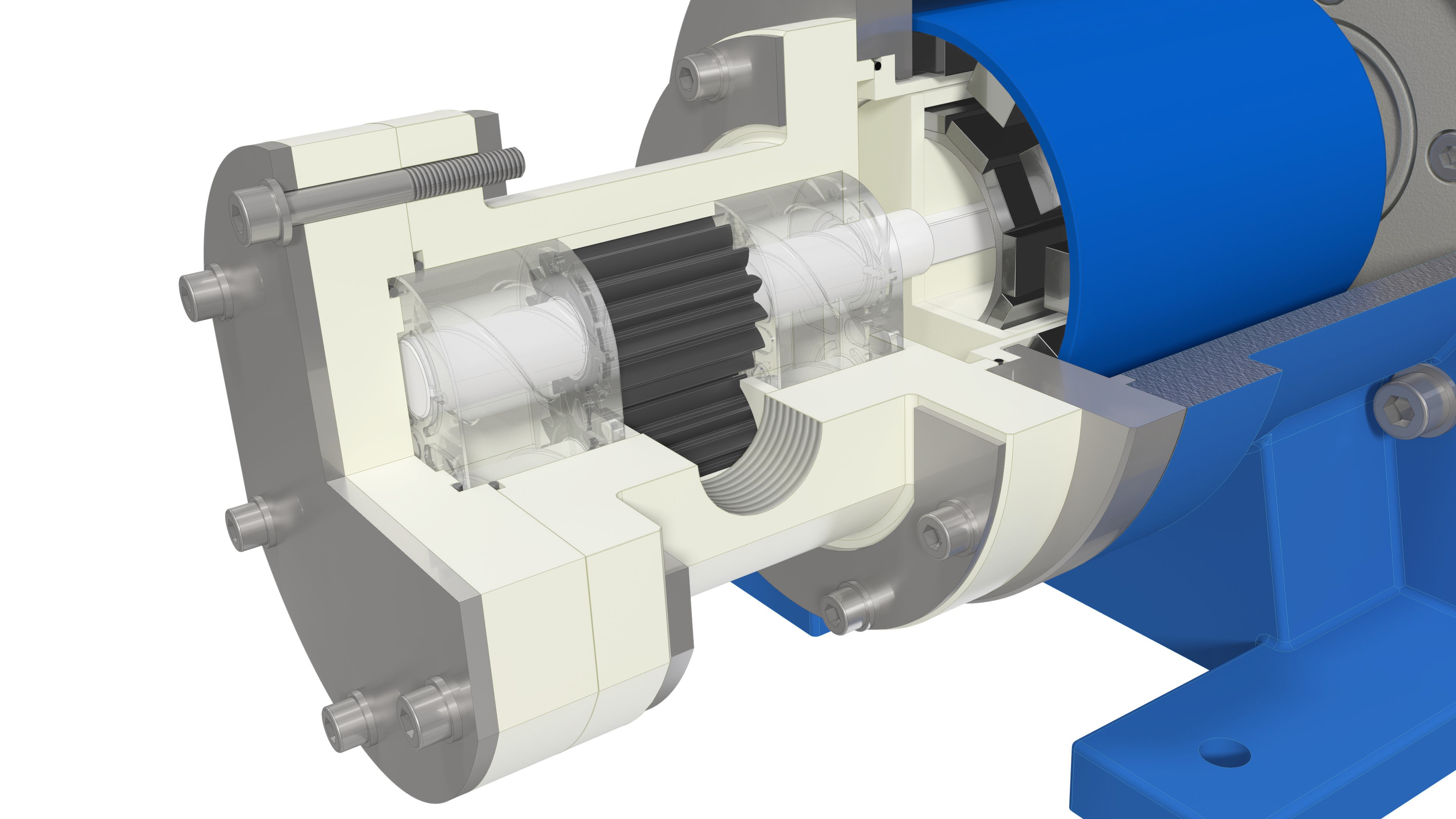

Patented gear pumps for highly corrosive liquids

TEF-MAG® - Series

Pumping corrosive liquids is a tough challenge for both machine and material. If the entire process is to be carried out without pulsation and at high delivery heads, rotating displacement pumps are usually the only choice. Pump manufacturers typically produce these only from metallic materials. So how do you move small quantities of corrosive liquids, pulsation-free against high back pressures, if a metallic pump is not an option?

MARCH PUMPEN has filled this gap in the market with specially developed and patented magnetically coupled external gear pumps made entirely of non-metallic materials.

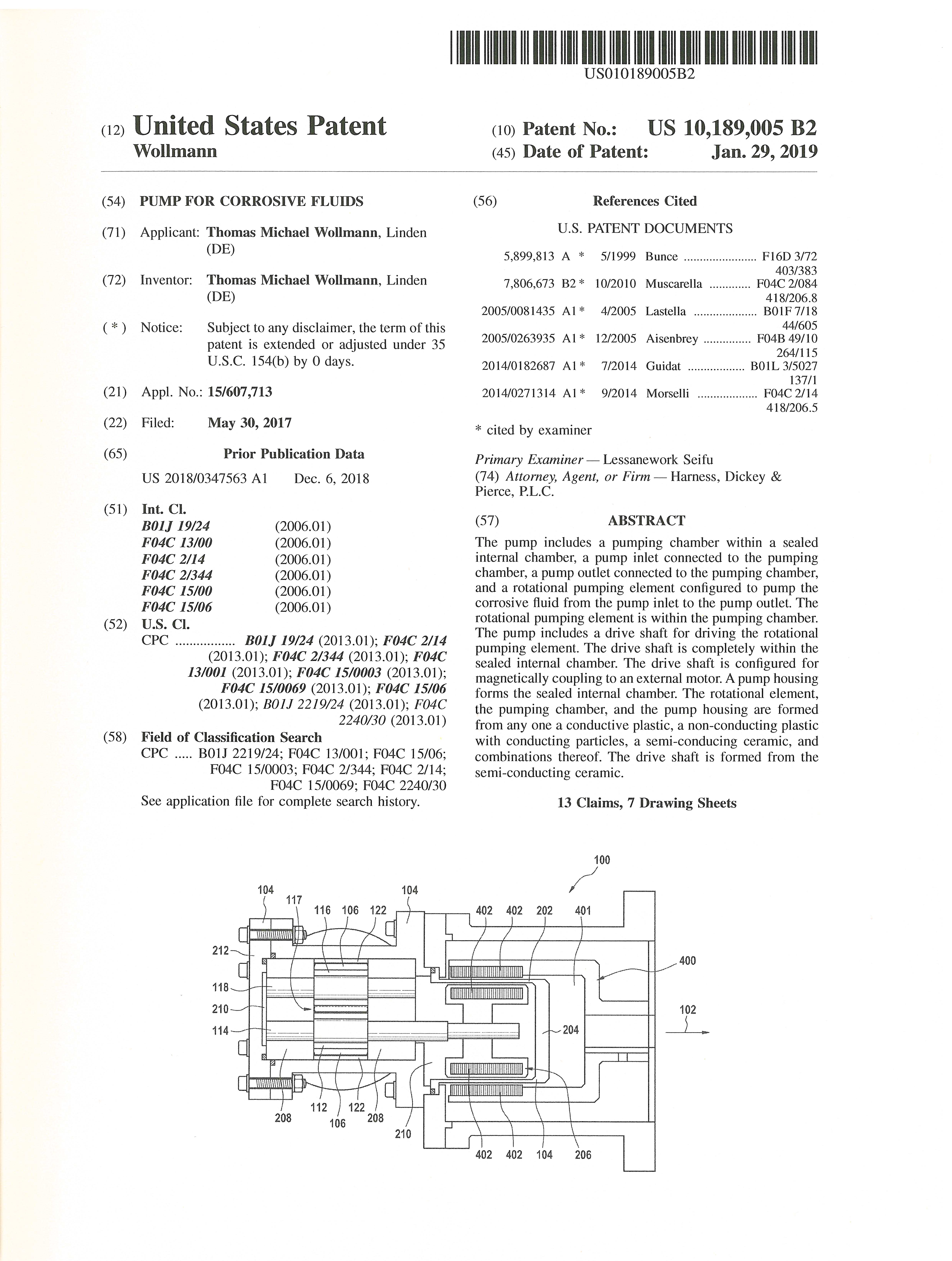

European Patent No. 3786416

US/Canada Patent No. US 10,189,005 B2

|

|

The TEF-MAG® gear pump series has been specially developed for operation with highly corrosive chemicals under the most extreme industrial conditions. The pump housings of the TEF-MAG® series are machined from solid material and corrosion-resistant polymers such as PP, PVDF, PEEK, PVC or PE. Also the wetted pump shafts, are made of non-metallic technical ceramics like SSiC or Al2O3, which represent the best possible chemical resistances. The gears are made of high performance polymers. They have self-lubricating properties. As a result, the pumps of the TEF-MAG® series are also capable of pumping liquids with low viscosity without any problems. Power is transmitted from the drive to the pump without contact, by strong NdFeB permanent magnets. This enables the pumps to operate completely hermetically and without any mechanical shaft seal, ensuring safe and leak-free pumping of corrosive, toxic and explosive liquids. Pumps for Zone 1 and 2 hazardous areas can also be supplied in corrosion-resistant and conductive polymers.

The range of applications is wide and covers almost any industry where corrosive liquids need to be dosed or pumped at high pressure, pulsation-free.

Application examples:

- As a chemical dosing pump in the accumulator recycling process

- As a dosing pump for neutralisation chemistry in waste water treatment

- As a catalyst pump in biodiesel production

- Pumping acids and alkalis, e.g. for CIP cleaning in food applications (FDA materials available)

|

|