Pentane Feed Pumps for PU Foam Production

Magnetically Coupled Rotary Vane Pumps: Ideal for pentane feed in the production of PU foam in metal composite elements and insulation panels.

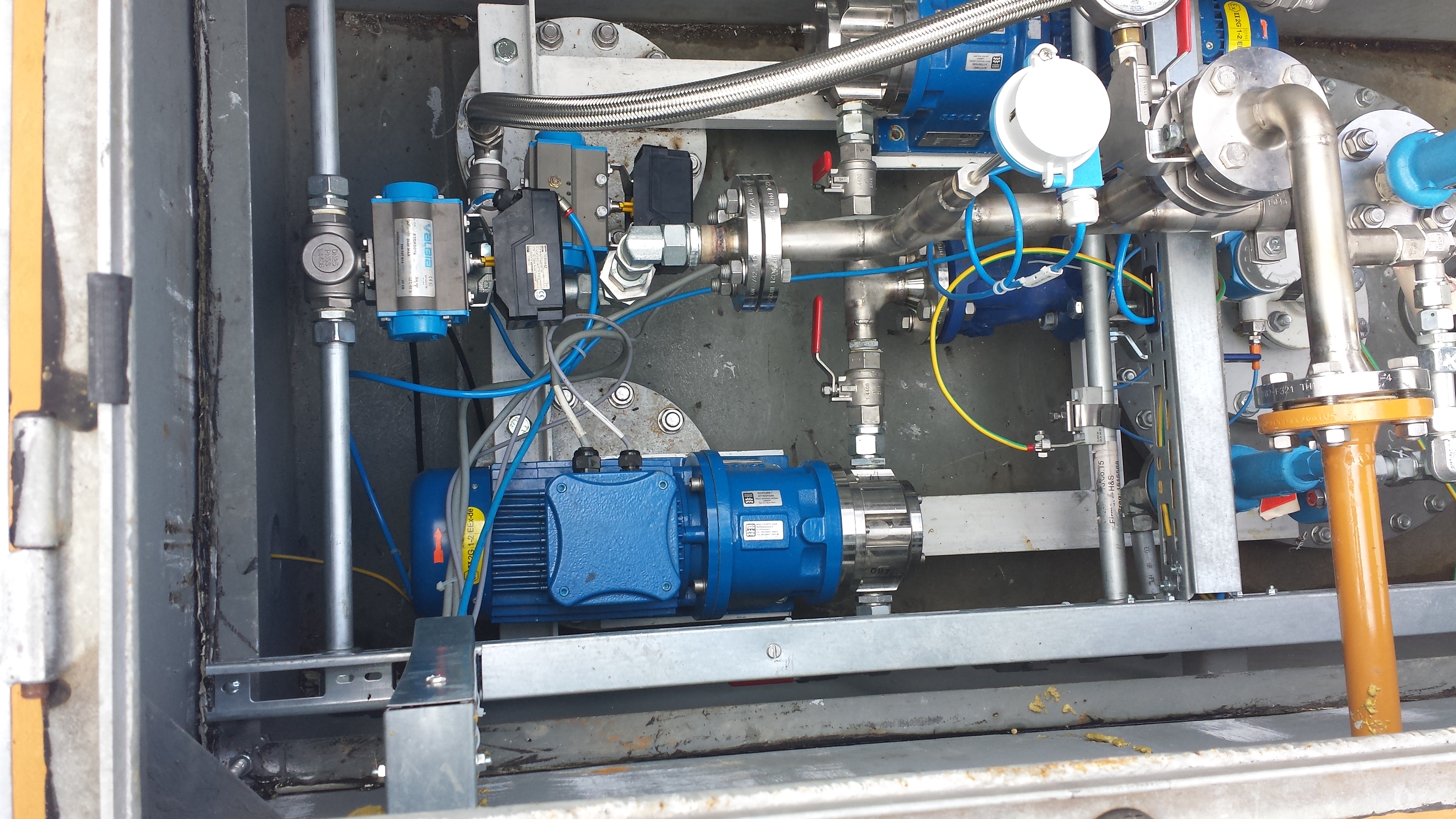

VANE-MAG® MPA- Mag Drive Rotary Vane Pump for PU Foam Production

Pentane, an organic compound with the formula C5H12, belongs to the alkane group and has three isomers: n-pentane, isopentane (also called methylbutane), and neopentane. In particular, n-pentane plays a central role in the production of polyurethane (PU) foam.

Nowadays, pentane is not only used as a CFC-free refrigerant in refrigerators and air conditioners but also as a solvent and for foaming phenolic resin and polystyrene. In PU foam production, pentane acts as a blowing agent. It is added to the liquid PU mixture and evaporates during foaming and hardening, thereby producing small gas bubbles in the material. This gives the PU foam its characteristic cellular structure.

Due to the flammability and high volatility of pentane, which has a boiling point of only about 36°C, special pump and system conditions are necessary. It is of paramount importance that the pumps operate without cavitation. Therefore, the NPSHA must be carefully determined and compared with the NPSHR. Usually, it should apply: NPSHA > NPSHR + 0.5m. It is also essential that no additional heat, especially at such a low boiling point, is added to the conveyed medium. Specific system conditions, such as low flow rates at high differential pressure, also limit the selection of suitable pump types.

Magnetically coupled rotary vane pumps ,also known as sliding vane pumps, of the VANE-MAG® MPA series offer ideal properties for this demanding process.

The pump hydraulics, consisting of axial thrust bearings, stator, and vanes made of carbon graphite, and sleeve bushings made of SiC, provide excellent self-lubrication for this low-viscosity medium. Non-metallic containment cans made of zirconium oxide, prevent additional heat input into the medium, as Eddy losses are eliminated. The low heat development, even in dry run operation, predestines this pump for use with pentane in an ATEX Zone 1.