Non-metallic acid pumps in the chemical industry

Pumps for chemical filling in chemical storage facilities.

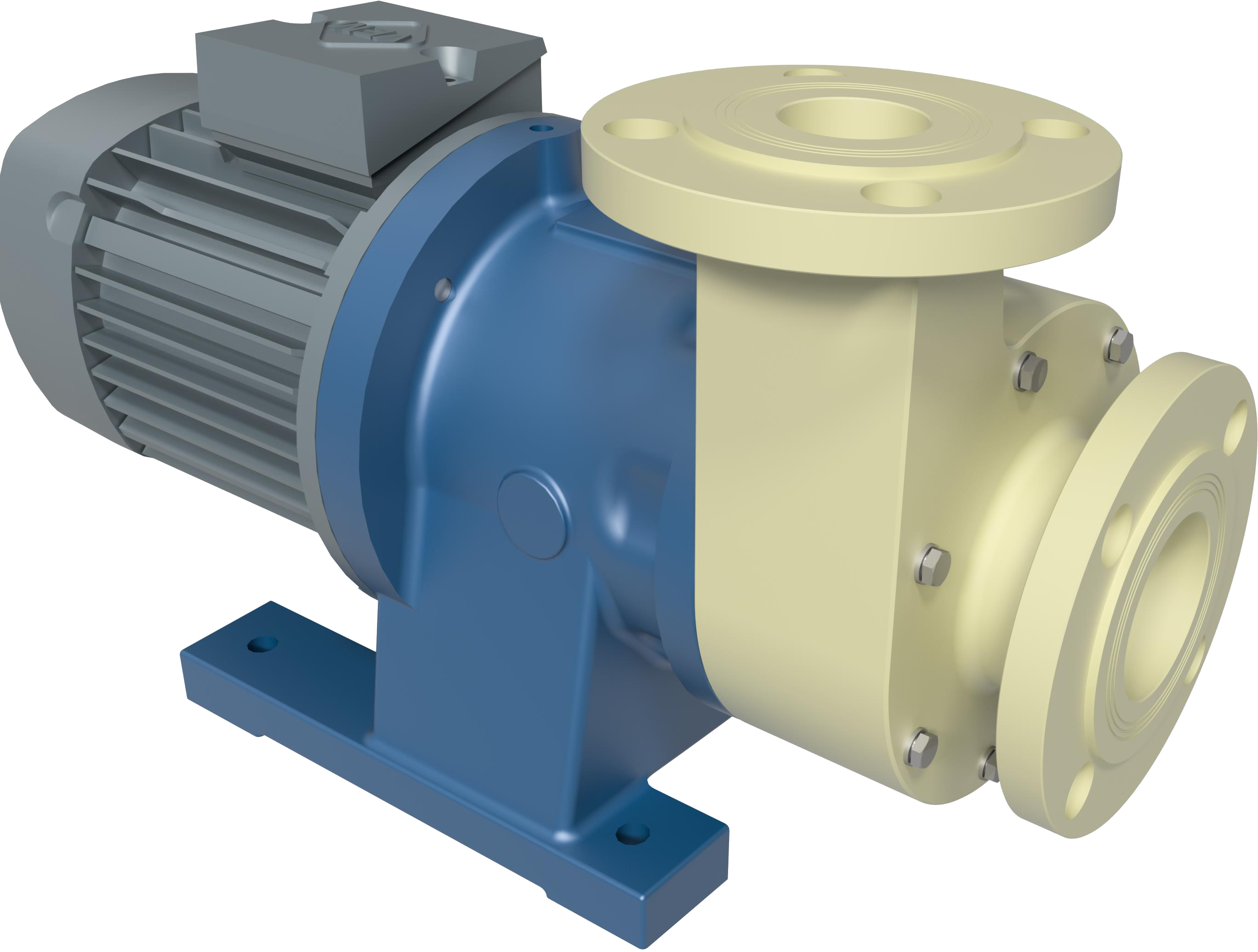

MCH series - Magnetically coupled chemical pump for industrial applications

When chemical resistance, robustness and durability are important! Then the non-metallic magnetic drive centrifugal chemical pump of the MCH series is the best choice!

As an innovative chemical company with numerous international locations, Zschimmer & Schwarz is a global player with customers all over the world.

In Lahnstein, the company operates a chemicals wholesale business where a wide variety of chemicals are delivered daily in tankers and then have to be filled into containers and other delivery vehicles.

In 1994, the chemical warehouse, consisting of about 30 large tanks, was completely equipped with MARCH magnetic drive chemical pumps of the MCH series. The plant builder was the globally active KUSTAN GmbH from Gelsenkirchen.

The challenging task was initially to standardize all magnetic drive pumps as far as possible in order to minimize the inventory of spare parts and maintenance costs and thus to reduce operating costs to a minimum. A competitive advantage here is the fact that all MARCH magnetically coupled centrifugal chemical pumps are completely maintenance-free, furthermore that the pumps were protected against damage from overload, dry running and operating errors by an external, electronic performance monitoring system.

Both tanker emptying and filling, right down to small containers, were to be realized with just one type of pump. This meant that all pumps had to be usable for a capacity range of 1,000 l/h up to 30 m3/h in order to keep the filling times and thus the downtimes of the delivery vehicles as short as possible.

Furthermore, the pumps had to be designed for the various properties of the chemicals, such as density, viscosity, and above all the chemical resistance of the different media.

Almost the entire range of different chemicals, such as phosphoric acid, nitric acid, sulfuric acid, caustic soda solution, hydrochloric acid, potassium hydroxide solution, etc., are handled in Lahnstein.

The pump casing of MCH chemical centrifugal pump is machined from the solid material, so it is extremely robust for industrial purposes compared with typical injection molding casing. In addition to using the durable pump materials such as PVDF and polypropylene, it was decided to use only SiC as the uniform pump shafts and bearings, which is chemically resistant to all pumped media.

The different densities and viscosities of the media were taken into account by using different impeller sizes, so that only one motor size could be used uniformly for all pumps.

All pumps have been equipped with an automatic pump monitoring system, type MARCH MASTER CONTROL (MMC), so that the pumps are automatically switched off after completion of the emptying or filling process in order to avoid dry running of the pumps, which is very important for increasing the service life. For residual emptying, the MMC can also be set with a run-on time, where the pump continues to run at a lower speed for a few seconds until the tank is completely empty.

Small container filling was implemented in Lahnstein with a clever frequency converter bypass system control, in which excess medium was fed back into the feed tank after container filling.

To date, i.e. even after more than 30 years of uninterrupted operation, in stop and go mode of the tank system in Lahnstein, only 3 replacement pumps and 6 replacement plain bearings have been supplied.

This confirms the longevity and robustness of the chemical pumps of the MCH series from MARCH PUMPEN.