Plastic Regenerative Turbine Pumps MT series

MAGNETICALLY DRIVEN REGENERATIVE TURBINE PUMPS

Horizontal, self-priming, gas entraining, single-stage, magnetic driven regenerative turbine pump in close-coupled design, all wetted pump parts made of non-metallic materials also according to ATEX 2014/34/EU.

MARCH magnetically driven peripheral pumps are available with different materials. The MTA series is made of stainless steel and the MT series is a non-metallic version. A large number of vanes produce comparably high pressure transport of small quantities. The MT/MTA series are finished with side channels allowing a transport of gas content in the pumped liquid up to 20 Vol % without causing dry running damage. Magnetically driven pumps operate completely without mechanical shaft sealing. Power is transmitted to the hydraulic part by strong permanent magnets in a contactless and force-locking manner.

MARCH magnetically driven regenerative turbine pumps are suitable for leak proof pumping of aggressive, environmentally hazardous and toxic liquids especially when low flow rates have to be pumped at high geodetic heads. The magnetic coupling ensures absolute hermetic sealing of the pump. The pumps are manufactured in a compact modular concept as standard. The modular building system allows quick replacement of individual parts without the need for special tools. European IEC standard motors according to DIN/EN 60034 and VDE 0530 are exclusively adapted as drives. All pumps of the MT/MTA series are available with pipe threads or flange connections. For a pump operation without malfunctions the application limits but especially the minimum flow rate and the required inlet head (NPSH, erf.) must be observed.

Features

- Regenerative turbine pump

- Non-metallic, chemical resistant

- Turbine wheel

- Leak-free

- Magnetically driven

- Up to 20 Vol % entrained gas transfer

- Self priming (wet)

- NdFeB / CoSm permanent magnets

- Modular concept

- Maintenance-free

- Only a few wearing parts

- Pump version also for ATEX 2014/34/EU

Technical data

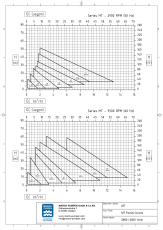

| MT series | Qmin [m3/h] | Qmax [m3/h] | Hmin [mWs] | Hmax [mWs] | Speed [1/min] | Materials |

|---|---|---|---|---|---|---|

| MT 2002 | 0,09 | 1,65 | 0,33 | 10,4 | 2900 | non-metallic |

| MT 2003 | 0,37 | 2,75 | 0,3 | 23,4 | 2900 | non-metallic |

| MT 3002 | 0,37 | 2,75 | 0,6 | 25 | 2900 | non-metallic |

| MT 3003 | 0,33 | 2,95 | 0,8 | 25,8 | 2900 | non-metallic |

| MT 5002 | 0,55 | 4,15 | 0,9 | 32 | 2900 | non-metallic |

| MT 5003 | 0,55 | 4,75 | 1,25 | 33,5 | 2900 | non-metallic |

| MT 7002 | 0,9 | 6,8 | 1 | 36 | 2900 | non-metallic |

| MT 7003 | 0,9 | 7 | 1 | 39 | 2900 | non-metallic |

| MT 9000 | 1,2 | 8,5 | 8 | 42 | 2900 | non-metallic |

| MT 12000 | 1,05 | 9,6 | 15 | 50 | 2900 | non-metallic |

| MT 16000 | 1,25 | 13 | 21 | 54 | 2900 | non-metallic |

| System pressure: | PN 6 up to PN 16 bar | |

| Temperature: | PP max. 65°C | PVDF max. 90°C |

| Density: | max. 1,8 kg/dm³ | |

| Viscosity: | max. 200 cP | |

Connections

| Pump version | Pipe thread (f) | Flange |

| MT 2002/3 | G 1/2" | DN 15 |

| MT 3002/3 | G 3/4" | DN 20 |

| MT 5002/3 | G 1" | DN 25 |

| MT 7002/3 | G 1" | DN 25 |

| MT 9000 | G 1" | DN 25 |

| MT 12000 | G 1 1/4" | DN 32 |

| MT 16000 | G 1 1/4" | DN 32 |

Materials

| Housing: | PP, PVDF |

| O-Ring: | EPDM, FKM, FFKM |

| Plain bearing: | Carbon graphite, PTFEC |

| Thrust bearing: | Carbon graphite, PTFEC |

Applications

- Neutralizations plants

- Wastewater treatment

- Chemical dosing

- Chemical technology

- Pharmaceutical- and Biotechnologies

- Pressure boosting

- Reverse osmosis