Gear Pump for Heavy Corrosive Liquids in the Battery Recycling Industry

Lithium-ion battery recycling plant, battery recycling

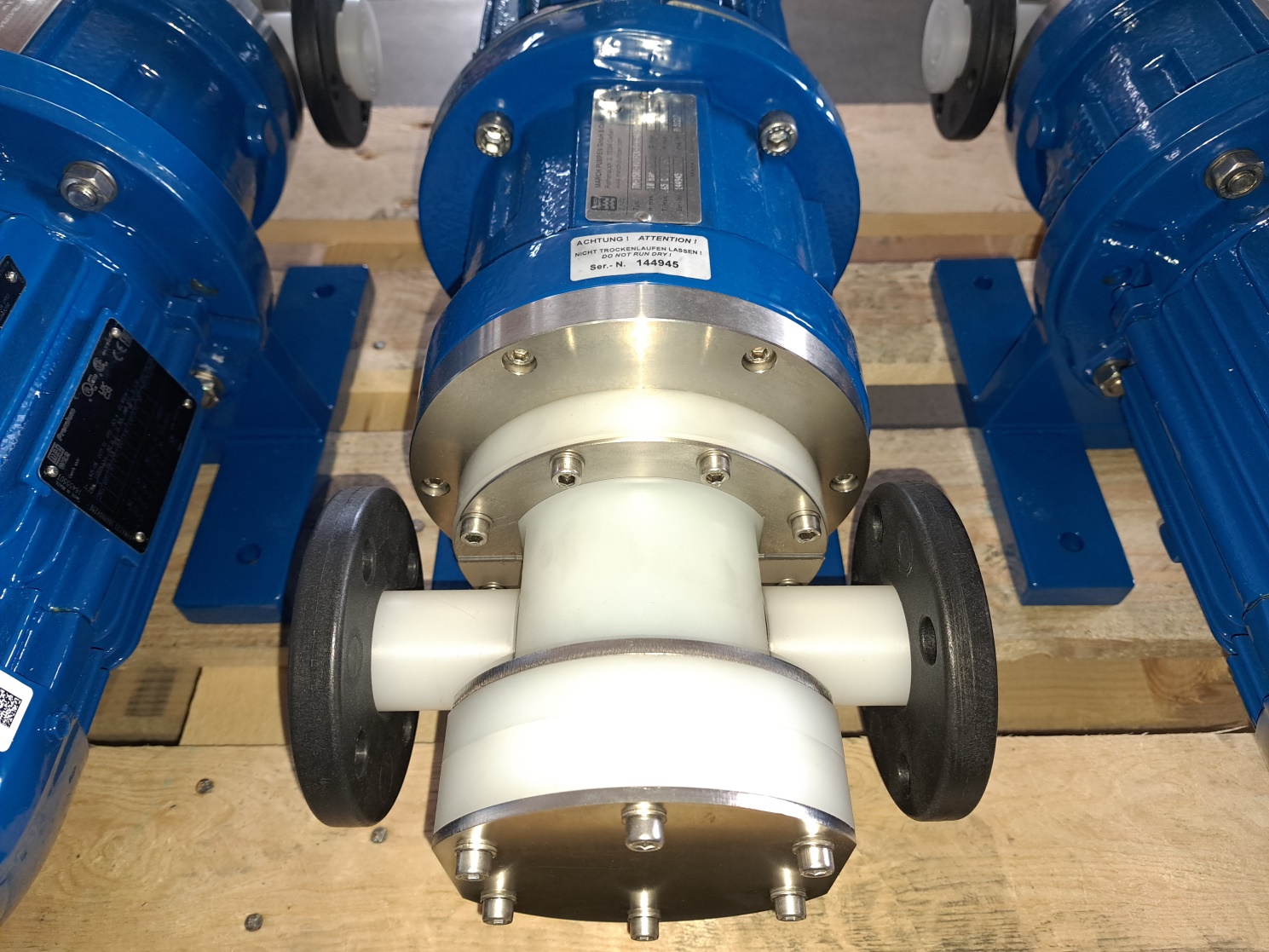

TEF-MAG® - chemical-resistant gear pumps made entirely of non-metallic materials for battery recycling

MARCH-PUMPEN supplies global plant manufacturers for battery recycling plants. In total, processing capacities of more than 15,000 tons of electric car batteries can thus be brought back into the value-added cycle. MARCH-PUMPEN thus actively supports sustainability in environmental protection by contributing to the avoidance of residual battery waste with the production and supply of the patented, chemical-resistant and magnetically coupled gear pumps made entirely of non-metallic materials of the TEF-MAG® series for dosing a wide variety of acids and other highly corrosive liquids..

In the process itself, the batteries are first mechanically treated to obtain the so-called "black mass", which consists of valuable raw materials such as lithium, cobalt, nickel and manganese. The black mass is then further processed hydrometallurgically using strong acids and other aggressive liquids. The metals are dissolved and separated in a special process.

Here, very small volume flows of highly corrosive process fluids of 5-1500 l/h at differential pressures of 5 bar or more must be dosed with low pulsation.

The patented TEF-MAG® gear pump from MARCH-PUMPEN combines the good dosing capability of rotary positive displacement pumps, chemical resistance through the use of completely non-metallic materials, as well as zero leakage through the use of magnetic coupling technology.

MARCH PUMPEN not only pays attention to the chemical resistance of the wetted parts. Components that are exposed to chemically aggressive atmospheres are also specially selected or treated. The pump lantern is manufactured from high-quality EN-GJS-400-15 and completely wet-painted in accordance with corrosion protection class C5 high. The drive motors are also specially designed for the harsh atmosphere. A variety of options, such as the VIK version, special wet painting, stainless steel screws, shaft and nameplates or even coating and treatment of the winding packs or the inner housing are possible.

Used pump types

| Housing | PVC and PVDF |

|---|---|

| Shafts | SSiC |

| Gears | PEEK, PVDF and PTFEC |

| Bearings | PTFEC and Graphite |

| O-Rings | FKM and FFKM |

Pictures