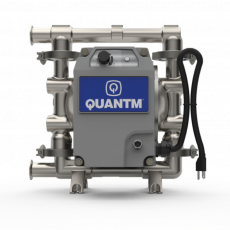

GRACO QUANTM series

ELECTRIC OPERATED DOUBLE DIAPHRAGM PUMPS

The QUANTM series is an electrically operated double diaphragm pump. By not using compressed air, it has up to 80% lower energy consumption. The control of the pump is integrated and all other advantages of a compressed air driven double diaphragm pump remain. The pump is perfect for almost all liquid applications and can replace existing pump technologies.

The housing parts, diaphragms, valve seats and balls are manufactured and installed from high-quality materials. Double diaphragm pumps are dry self-priming, dry-running safe and can easily convey liquids containing solids. Even viscous or volatile fluids are not a problem for the double diaphragm pumps. Thanks to these features, the QUANTM pump series is one of the most reliable double diaphragm pumps on the market. The electric motor eliminates the need for compressed air and reduces energy consumption by up to 80%. ATEX or FDA models are available on request.

Design Features

- Up to 80% less energy consumption than air driven pumps

- No icing

- Insensitive to cavitation

- Leak-free

- Resilient

- Corrosion-resistant

- Self-priming, wet and dry

- Capable of dry running

- Handle fluids loaded with solids

- High quality materials and finish

- Pre-wired for quick installation

- 120V and 240V options

- Models also available for ATEX Class 1 Zone 1 AEx db IIb T4 Gb

- FDA certified

Technical Data

| QUANTM series | DN [Zoll BSP] | Qmax [l/min] | ΔPmax [bar] | Material |

|---|---|---|---|---|

| QUANTM i30 | 1" | 115 | 7 | metallic / non metallic |

| QUANTM i80 | 1,5" | 300 | 7 | metallic / non metallic |

| QUANTM i120 | 2" | 450 | 4,2 | metallic / non metallic |

Materials

| Housing: | Aluminium, Stainless Steel, Hastelloy, PP, conductive PP, PVDF |

| Membrane: | Santoprene, Buna, PTFE, FKM, Geolast, Hytrel |

Applications

- Barrel or bulk unloading

- Transfer, circulation and feeding systems

- On-Demand bulk dosing

- Chemical supply

- Dewatering, sump draining

- Acids, alkalis, solvents, liquefied gases, polymers

- Abrasive and corrosive fluids

- Ceramic glaze / slurries

- Adhesives

- Paints, lacquers

- Water, wastewater

- Used oil

- Sludge, sewage sludge