Biodiesel and glycerine: from waste to main product

Optimization of production processes at NEW Biodiesel through the use of TEF-MAG® gear pumps

NEW Natural Energy West GmbH is a company that specializes in the production of biodiesel and the processing of glycerine. NEW uses various pumping media and chemical reagents in its production processes. This case study focuses on the optimization of biodiesel production through the use of the chemical-resistant TEF-MAG® gear pump made entirely of non-metallic materials, as well as the transition from glycerine as a waste product to the main product.Transition from glycerine to the main product in the biodiesel industry:

The transition from glycerin, once considered a waste product, to a mainstream product in the biodiesel industry is closely linked to developments in biodiesel subsidies and regulations in the late 1990s and early 2000s. During this period, there were generous subsidies and incentives for biodiesel production in many countries, which led to rapid growth in the industry.

The high demand for biodiesel as an environmentally friendly fuel led to increased biodiesel production. This increased production resulted in an increased yield of glycerine as a by-product. As biodiesel production was heavily subsidized, glycerine was initially a waste product that often had to be disposed of at great expense.

Over time, however, subsidy policies and market dynamics changed. Subsidies for biodiesel were reduced or discontinued, leading to an oversupply of glycerin and drastically lowering the price of this by-product. In response to these changing economic conditions, companies in the biodiesel industry looked for ways to use glycerin more efficiently and produce higher-value products from it. This contributed to the transformation of glycerine from a waste product to a mainstream product.

Adapting to changing subsidy and market conditions was a key factor in the re-evaluation of glycerin in the biodiesel industry and its transformation into a valuable primary product.

Challenge:

NEW Biodiesel faced challenges in terms of efficiency, quality and sustainability as the transfer and metering pumps previously in use were failing at regular intervals. Production downtime due to pump failures affected productivity and led to unnecessary business interruptions. The maintenance and replacement of the pumps caused additional costs and increased the need for spare parts and man-hours. Additionally, the challenge was to meet the safety requirements for operation in ATEX Zone 1 while minimizing the environmental impact. The company was looking for a solution to extend the service life of the pumps, reduce operating costs and ensure safety in the plant.

Pumped media used in the production process:

1. methanol:

Process engineering process: methanol is used in biodiesel production as an alcohol component in the transesterification reaction. In this process, methanol reacts with vegetable oils or animal fats to produce biodiesel (Fatty Acid Methyl Ester, FAME) and glycerine. The methanol molecules replace the original glycerol molecules in the triglycerides of the raw materials, enabling the conversion to biodiesel. Methanol is a key ingredient and driving factor of the biodiesel production process.

2. sodium methylate 30% in methanol:

Technical process: Sodium methylate is a catalyst used in biodiesel production to accelerate the transesterification reaction. It is dissolved in methanol and is added in this form. The catalyst promotes the conversion of triglycerides into FAME and glycerol. The addition of sodium methylate in methanol increases the reaction speed and efficiency of the process, resulting in higher yields of biodiesel.

3. hydrochloric acid 5-30%:

Process engineering process: Hydrochloric acid is used as a catalyst in the transesterification reaction in biodiesel production. In this process, hydrochloric acid accelerates the conversion of triglycerides into Fatty Acid Methyl Ester (FAME). The exact concentration and application of hydrochloric acid can vary depending on the specific requirements of the production process. It is critical to ensure that the amount of hydrochloric acid used meets the process objectives while being safe and environmentally friendly.

4. biodiesel (FAME):

Technical process: Biodiesel, also known as Fatty Acid Methyl Ester (FAME), is the end product of the biodiesel production process. After the transesterification reaction is complete, the biodiesel produced is extracted from the reaction mixture. This biodiesel can then be pumped and stored in storage tanks before it is ready for distribution and use. FAME is the main fuel resulting from biodiesel production.

5. caustic soda 30%:

Technical process: Sodium hydroxide, also known as caustic soda, is used as a catalyst in the transesterification reaction during biodiesel production. The addition of caustic soda promotes the conversion of triglycerides into Fatty Acid Methyl Ester (FAME). The concentration of caustic soda can vary depending on the specific requirements of the production process and is used to optimize the pH value of the raw materials and to neutralize acids. It is important to carefully control the amount of sodium hydroxide to ensure an efficient reaction and maximize the quality of the final product.

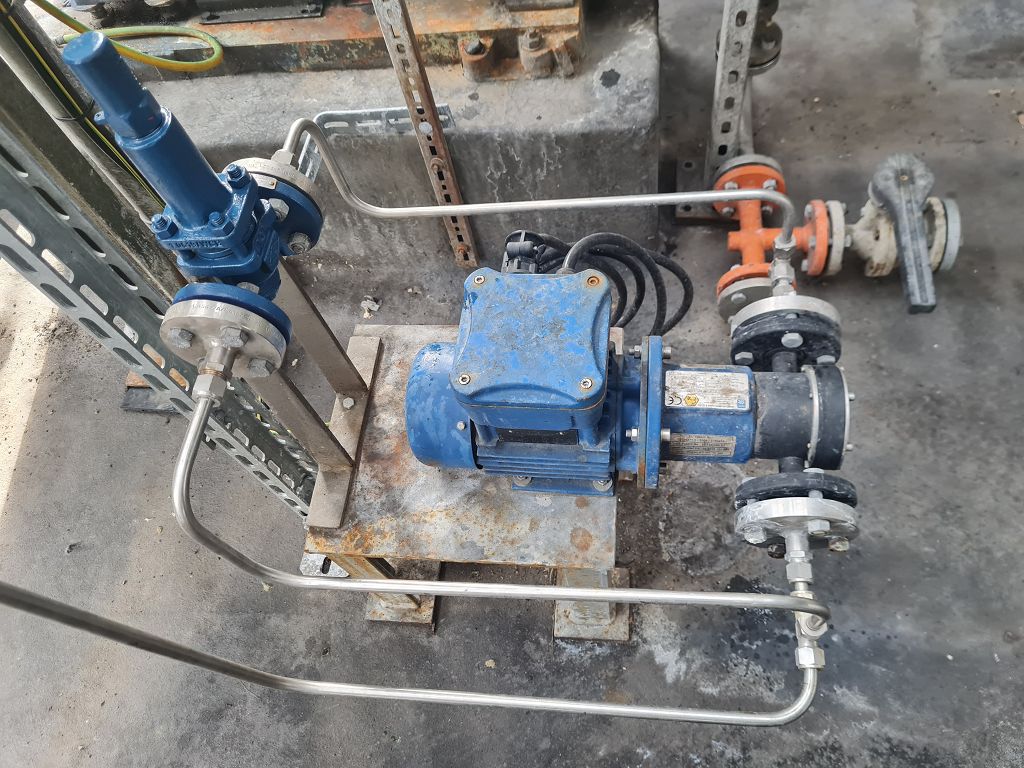

Pump solutions from MARCH PUMPEN:

The TEF-MAG® chemical gear pump from MARCH PUMPEN has been specially designed for such requirements. Due to the completely non-metallic wetted parts and the wide range of possible materials, the pump is the best choice on the market when it comes to chemical resistance, long service life and process reliability. The pump is successfully used both as a transfer and dosing pump.

TEF-MAG 200: